Quality First,

From Source to Shipping

Systemized Control × Data Monitoring × Human Validation

for Consistent Excellence

Quality Management

Our quality framework spans the entire lifecycle—Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Outgoing Quality Control (OQC)—with standardized SOPs and AQL sampling. We apply Statistical Process Control (SPC) to monitor critical parameters and conduct reliability tests tailored to connectors and cables, including dimensional checks, insertion/withdrawal cycles, contact resistance, flex/tensile tests, salt-spray, and environmental stress. Measurement tools follow a defined calibration schedule with MSA to ensure trustworthy data. Every lot is fully traceable via barcode/lot IDs; any abnormality triggers 8D/CAPA for rapid containment and permanent corrective action. By combining robust systems, actionable data, and experienced inspectors, we make quality measurable, traceable, and dependable—on every shipment.

X-Ray Fluorescence System

For Hazardous substances test

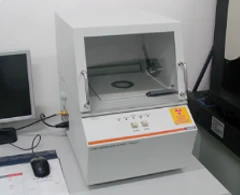

Thermal Shock Tester

X-Ray Spectrometer

For Plating test

Programmable Temperature and Humidity Chamber

Salt Spray Tester

X-Ray Inspection System

Steam Aging Tester